Okay, so here is the scoop. I worked on fans/motors like this professionally for decades.

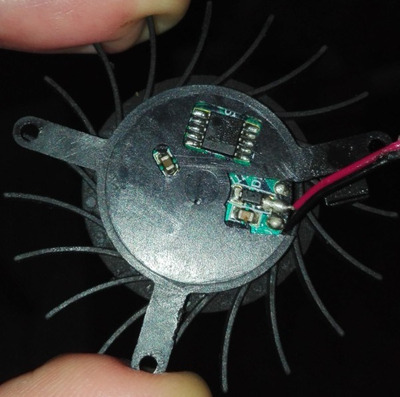

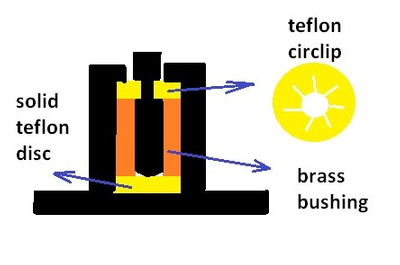

Basically many of those fans use a dry slip bearing. But not all. Ideally you would try to clean them and insert something like graphite in them, but good luck with that.

Long story short, they aren’t supposed to need oil, and in fact, adding oil can actually sometimes lead to a failure soon after.

With the dry slip bearing type if the fan siezes up what you need is wd-40. Why? Because it isn’t a good lubricant only marginal at best, it evaporates eventually, and it is a a decent solvent. Also, and this is key, it is not very electrically conductive, though the contaminates it dislodges can be. But that is unlikely to cause a issue on a 12v fan.

The key here is the combination of properties helps free the bearing and clean it. And eventually it returns to its natural state

If the fan uses a ball/roller bearing, you can end up seizing that up with oils as they collect dust and make gum. Just like the previous problem if they aren’t sealed. See, fans are exposed to lots of dust and no new source of oil or cleaning usually.

But,

Many fan failures are worn out plastic bearing cups or worn out bearings themselves.

Again, don’t use oil on fans, but if you do, use wd-40

Basically if it is stuck, you can probably fix it, but if it is wobbly, or squeaky, you are only buying time. Best to replace.