First post, by Sphere478

- Rank

- l33t++

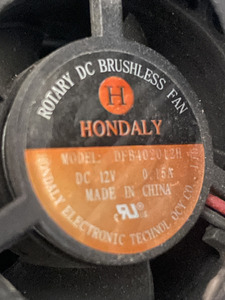

I am in need of some military grade fans for a project, this project will experience the arizona heat and very hot equipment (as much as 100c) these need to be able to run 12 hours a day every day for decades without failure or any maintenance whatsoever they will be buried deep in the equipment and can not fail because their failure won’t be detected and will result in equipment failure, weeks of down time and many hours and 700$ lost each time one fails.

Since I know you all are curious,

These fans will be upgrading the fans in solar charge controllers the fans that are in them have been repeatedly failing every couple years and it has been costing a fortune and much frustration to fix them each time it happens. I need to get ahead of this. Need better fans.

I will follow up with pics and sizes of current fans which need replacing.

Note that a higher cfm unit is highly desirable as it will allow more solar harvesting on hot days and keep the units from throttling. Unfortunately the throttling doesn’t protect from total fan failure.

I know this is the crowd to ask because if anyone know’s fans, it’s you all.