First post, by Splinter

- Rank

- Member

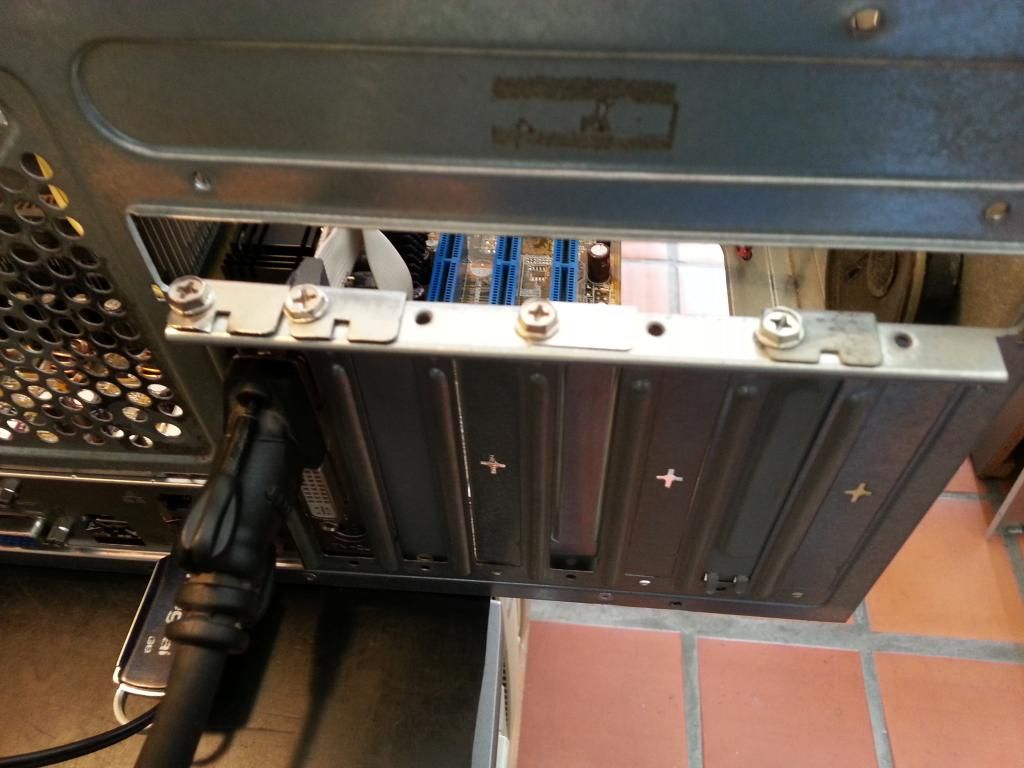

I've only ever seen these here in Argentina and can't quite see the point of having the card bracket fixing point actually outside the case. You have to take the side off anyway.

There's a little cover that screws over it.

http://www.compufixshop.com

Main rig Ryzen 2600X Strix RX580 32GB RAM

Secondary rig FX8350 GTX960 16GB RAM