Jorpho wrote:

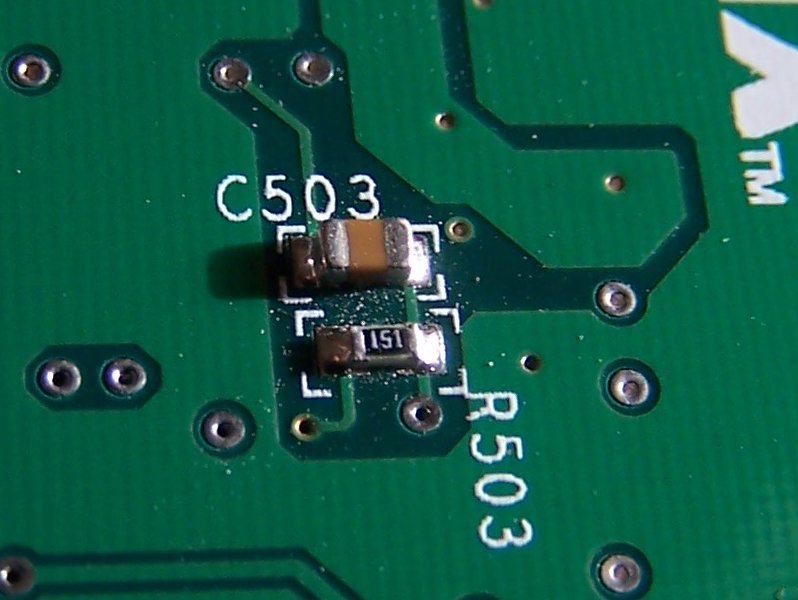

Another question: I can see in this case you would apparently need a 150Ω resistor. But, assuming there's space, do you really need to use an SMD resistor, or will an ordinary resistor with big gangly leads do just as well, especially considering it wouldn't be going into an especially-cramped space?

I've replaced several surface-mounted resistors with plain old resistors and have never had a single problem other than ripping a few traces here and there. Here's my suggestion if you're going to use a standard resistor rather than a surface-mount resistor:

1) Solder 2 pieces of IDE ribbon cable, one on each end of the solder spot

2) Solder the leads on the resistor to the other ends of each wire

This will make it less likely for you to rip a trace off the PCB.

And yes, that is a 150ohm resistor.