Good information. Nobody ever mentions how long the citric or acetic acid should be soaking on the traces. I tend to let it sit for only 5 minutes, but not sure if that is optimal.

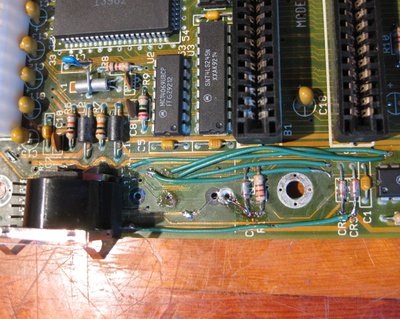

I still see blue corrosion on your board. Look at the traces under CR5.

Also, what I normally do is:

a) first scratch off all the laquer on the traces which have evidence of lift-off (there are darker splotches of different colour on the traces). There is usually quite a that carbon carbonate, which feels and acts a little like rust. I scratch all of it off.

b) I clean out all the vias and surface corrosion by physical removal (rubbing off). I get all the blue out of there and all of the non-shiny copper removed. Then I brush it dry with a soft toothbrush. This usually involves removing several components and headers, as you have done.

c) I am in the beginning of forming a theory that the battery electrolyte can hangout inside those little inductors (L2, L3, etc). It might turn out false, but it might be worth while to replace them if they are being removed anyway. They are usually for the keyboard data/clock and mouse data/clock and are almost always either 1 uH, 2 uH, or 4 uH. Sometimes I see the keyboard using 4 uH and the PS/2 mouse using 1 uH, but sometimes there are 2's. For simplicity, I have a bag of 2.2 uH inductors around (e.g. 78F2R2K-RC). They are rated for 630 mA, which is about double the max. for PS/2 keyboard/mice.

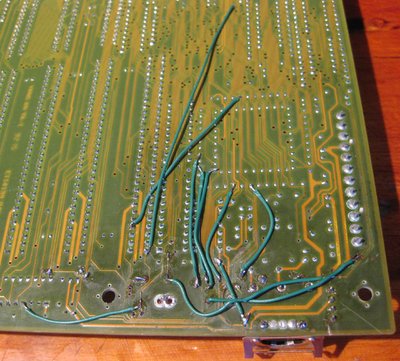

d) Once all is brushed away dry, I brush it with water, then dry it with compressed air. Then I take varying sizes of wire guage (22, 24, 26, 28, and 30 AWG) and stuff them through the through holes and via to sorta of scrub them like flossing teeth. I want all of the reacted gunk (which we've been informed is copper carbonate and copper oxide) out of there by physical removal before neutralising it with acetic acid. This might take another hour.

e) Now I brush on the vinegar (acetic acid) and let it sit for 5 min. Again, I'd like some clarification on how long this reaction will take. I suppose it depends on the depth of the residue, but by now it should be quite thin.

f) Then I rinse off the vinegar with tap water and use compressed air to blow away as much water as possible.

g) I stick the motherboard on the floor of the powder room and a heater set on low (~600 W setting) for 20-30 min.

h) I now check all the questionable traces for continuity with my multi-meter and fix where appropriate. I also check the questionable inductors and capacitors. On traces which look like they have very little copper completing the traces, I bridge a wire over the area to increase its current carrying capability, usually on the larger 5V traces.

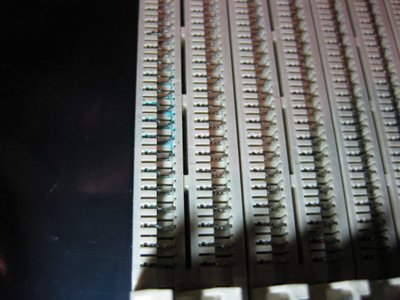

i) One last dry brush, then a rise with ISO. For headers that I removed, I usually replace them with new ones.

Plan your life wisely, you'll be dead before you know it.