First post, by Intel486dx33

When you solder on new capacitors do you apply some flux first to the area so the solder will adhere better ?

Or do you just solder it dry ?

If so what type of flux do you use ?

I find that when I try to solder dry it does not adhere well to the PCB area and usually burns the PCB.

If I add some No-clean flux it adheres better and does not burn the PCB area.

I want to know what is the best type of flux to use ?

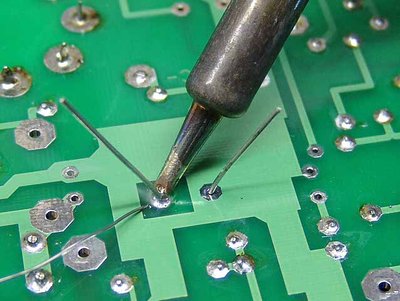

Also I add the solder to the iron tip and not to the capacitor PCB area.

Once I have the solder iron loaded with some solder I then just touch the PCB/capacitor leg and the solder flows on to make the bond between the capacitor leg and PCB.