First post, by Cga.8086

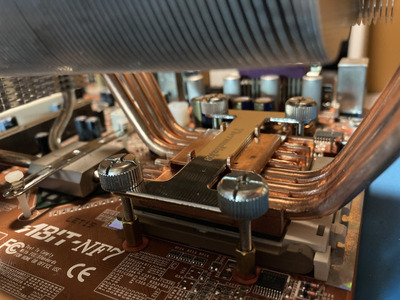

I got this cooler when i bought a box full of hardware. Thermaltake big thypoon.

it is supposed to be one of the biggest coolers of its era.

i was not able to find the installation manual online, since it was replaced with the VX version and the clamps are all different. Does anyone own this cooler? I need to know how it gets installed.

- The gren arrow shows 2 things, a thin layer of plastic bracket, and a thick layer rubber bracket (i belive this goes on the back of the motherboard.

-the blue arrows shows two brackets, i think one goes on the front and one on the back of the motherboard.

- But what is the red bracket for??? i don´t get whats the use of it, as the holes in it... match some holes on the blue bracket.