Just making replacement parts from existing is tough work, either you'd have to:

- Make moulds

- Design from scratch - only really do-able for the libretto, even then that's a complex structure

- 3d scan

I've never seen the original CAD data floating about online, which you'd need to create replacement parts with. Or perhaps the things the parts are molded from

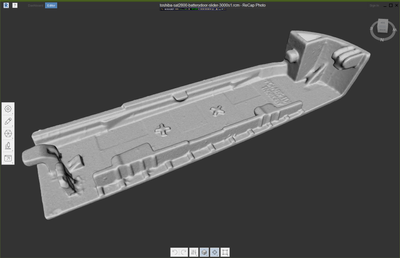

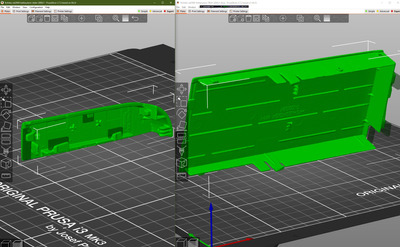

I have a 3d scanner and the tech is improving but it's tough work and requires a fairly high end photogrammetry or 3d scanning capture setup to get enough detail to make functional replacement parts. Just making up this battery door was a couple of days work and that's with the 3d scanner already dialled in and me knowing how to work all the software. Notably though, this is the first design where I relied purely on scan data rather than going into Fusion 360 / parametric CAD, instead just using the 3d printing slicer software to add on parts and fix areas.

The trouble is, bits where there are mechanisms or where one part interacts with another, are notoriously difficult to scan since they can only be seen from a few angles meaning the scanner can't fully determine the 3d shape of parts it can't see.

Just this battery cover took ages to print and the detail of FDM is almost not enough for the parts to work and fit properly in my Satellite 2800-500. Why'd I do this btw? Well I have two 2800-500 laptops one without the battery cover and parts for it seem to be entirely unavailable. I'm not 100% happy with the outcome since the slider doesn't stay attached but it's doing the job.

It'd be easier with some of the older laptops where like the tub chassis is a bit rectangle with some protrusions but then how to get it made? Resin works for small parts and FDM is good for big parts, but around the size of an A4 page and you'd need to break up a part into multiple pieces or get a bigger printer.

3lectr1c wrote on 2024-05-04, 23:08:Thanks for the SENS 800 hinge guide, I need to loosen the ones on my unit that I recently acquired.

No one has 3D printed a whole new case because that wouldn't make sense for 3D printing technology. It's not the right texture, printing large durable parts isn't really doable for most setups, etc.

And there's this, FDM printing gives a rough surface finish and can be weaker at the same density as an injection molded part because of layer lines and imperfections. Resin is hard to get dimensionally accurate from what I've seen and can be weaker than FDM especially for big flat surfaces like the underside of a laptop.

There are 3d printing services that can do that though with more advanced printers that make stronger parts with better surface finishes. That might be better but the costs are not low, especially if more than one design iteration is needed.

IMO, where plastic parts can be repaired they should be - even when they're missing entirely 😜 Re: What retro activity did you get up to today?

But maybe that won't work forever and some of the plastic mixes i.e. glass fiber reinforced plastic are breaking down quicker than others. It would not be a small task to make replacement housings even for a select few models, but there are so many variants of laptops that'd be a mind boggling amount of work.