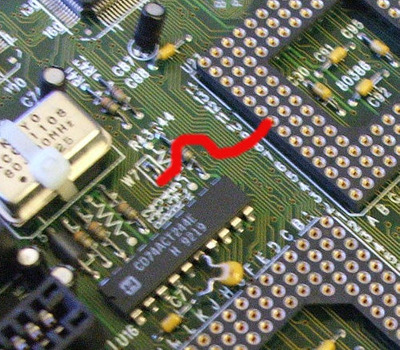

Today happened the strangest thing. The board since I booted seems that was a bit unstable. At first I was blaming the floppy disks I have mostly gone, then I was thinking I was using too fast caches (15ns vs the 20ns of the specifications), then I was thinking to some incompatibility with different isa cards.

But today the vga output began to be darker almost not visible! Changed different vga and same thing!

Tried changin cache, removing everything even the board from the case, nothing. At the end do you know what it solved back the situation to the normal vga signal? Using a original AT psu! I suppose even if I can't imagine why, the ATx to AT converter without the -5v or the psu I'm using (is a still good Enermax one with very stable 5,0 and 3,3 volts but lacking the -5v) was the problem.

So I've to pause the project while searching for an AT case and maybe finding a good AT psu or cleaning and checking the one I've that is far from "high end" (thin wires, few components..). Another AT psu I tried first (on another mainboard fortunately, like I was already looking at the future...) once pushed the power button did " a bad light and sound" as usually when capacitor are gone badly. I've still to check it inside but I'm sure it was ok some time ago...

There's no way with old AT psu it always get scaring to power boards or components you care about.

But before stopping the project I did some tests:

3DBench: 15,8

Speedsys: CPU 6,33 / Vesa mem: 3667 Kb/s / L2-256Kbytes: 27,41 Mb/s / Main memory: 12,39 Mb/s

Cachechk: 256Kb L2: 27,8MB/s Main mem: 9,4MB/s Ram access read: 222ns Ram access write: 104ns

Quake did run so I suppose the IIT FPU is running ok! 😁