First post, by my03

Hi all,

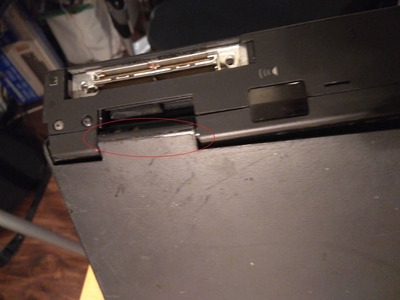

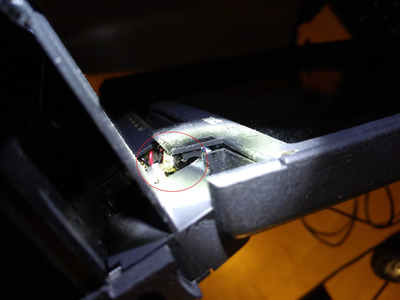

unfortunately, my "butterfly" decided to make life difficult and cracked the screen on the left-hand side where the hinge is. The actual screen cover is not too busted, but the hinge itself peeks out on the back 🙁

I have found the hmm for this model (including a bunch of others in the same document) and i'm going to make my absolute best to restore it as good as i can. While reading up on this particular model online, i often come across descriptions of disassembling it as a nightmare (some even say that some service-centers were not allowed to do it themselves, but had to send them to IBM to fix them).

How bad is it really? Have anyone successfully fixed a similar issue? Since spare parts for this model seems to be unobtanium, my plans are (if possible) to take it apart so much so that i can detach the lcd-assembly (inkl. facia and cover) and see if i can "loosen up" that hinge somehow, then try to "glue" it back again as neatly as possible. Would that be feasible?

I had to do the exact same thing to a much newer machine that i have (Y50-70) that i got fairly cheap that had a cracked hinge attachment against the back-plate and in that case, i could just order the spares and loosen the hinge-screw somewhat (after lubing it), after which it was like new again.

Any advice?