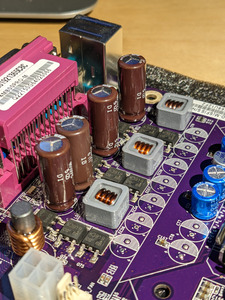

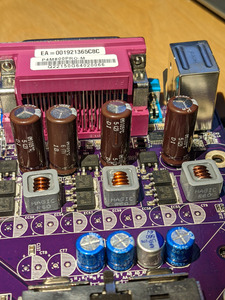

As soon as just one cap of a given type shows the slightest sign of bulging, leaking or otherwise physically changing, it needs replacing and so do all other caps of same type on the board. Usually physical symptoms only become visible after significant electrical degradation has already occurred.

That said: will this board explode and set fire to your house if you just briefly plug it in - probably not, although you don't want to have your eyes anywhere near those caps as you might get a corrosive, toxic fountain coming out of them. Depending on what I wanted, I might risk doing some testing, but then again, it doesn't really add anything: if it's not booting, or booting but not stable, the caps are most likely implicated and need swapping. If it is booting and stable, it won't be for much longer with caps in this state, so the caps need swapping... I'd just swap the caps.

As for how difficult - that depends on your tools. This board is new enough to have ROHS lead-free solder, which is a PITA that needs a lot more heat than older toxic lead solder.

What I would do if this was my board:

Prerequisites

- replacement caps, good brand (Panasonic, Nichicon, Sanyo etc) from a reputable electronics vendor. Ensure capacitance and pitch (pin spacing) are exact matches, and that rated voltage is at least the same. Ideally you want to match ESR as well, but probably these shitty caps never lived up to spec (if you can find it...) anyway, so just go for generic low-ESR caps and you should be good.

- a decent soldering iron. I'd say at least 30W because ROHS and ground plane.

- thin fresh solder, preferably easy-to-use leaded stuff

- flux

- if possible a desoldering pump (simple plastic spring-loaded one is probably good enough). Some people swear by copper braid, but it doesn't generally work for me, at least not as a full alternative for a pump

Desoldering

- clean the underside of board well

- apply flux to the pins

- solder blobs of fresh solder onto the pins

- heat the first pin well. You want the new solder to mix with the old stuff and make it softer

- when it looks like everything around a pin is liquid, suck it out with the pump, apply braid or failing any of that, try physically moving the cap (lean away from the side you're working on) to pull the pin out. You'll notice that the + goes much faster than the -, which is connected to a big ground plane, that sucks up huge amounts of heat. If this doesn't work, solder on another blob of new solder, heat it all a bit longer and try again.

- repeat for second pin

- after getting the cap out, clean up the holes. You might need a few more drops of fresh solder for this. Suck/braid out as much as you can. At the very least you need enough of a depression to get the new cap leg into when you start soldering, but preferably the whole hole should be clean with no mess around it on the PCB either.

- repeat for other three caps.

- dispose of old caps as chemical waste.

Soldering (the easy bit)

- get new cap and line it up correctly. The stripe on the cap is the negative (-) pole and MUST be lined up with the negative side (white semicircle in this case) on the board. Failure to get this right results in exploding cap at first power on!

- if you managed to completely clean the holes, then it's easy:

-- stick in new cap

-- apply flux

-- heat first leg

-- apply solder to the hot leg until it melts & fills the hole

-- repeat for second leg

-- trim off excess leg length

- didn't manage to completely clean the holes? then more fun:

-- apply flux and blob of new solder to blocked hole on bottom of board

-- hold cap in place on top side with light pressure (so it will sink through hole as soon as possible, but not so hard you bend the leg)

-- heat the new solder blob over hole on bottom of board while keeping pressure on cap

-- if all goes well, the leg should go through once solder in hole is soft enough

-- repeat for other leg

(you may find not having a third arm is a bit of a handicap while performing this sort of shenanigans... 😉 )

Either way, when it's done, clean off any solder and flux residue. Then you're ready to test.

If you've never done this before, I'd strongly recommend practicing twice first on bits of electronics you don't mind ruining:

1) something from before 2000, with good 0ld leaded solder (easy)

2) something from after 2003, with ROHS certification (hard, comparable to the motherboard)