First post, by Kahenraz

- Rank

- l33t

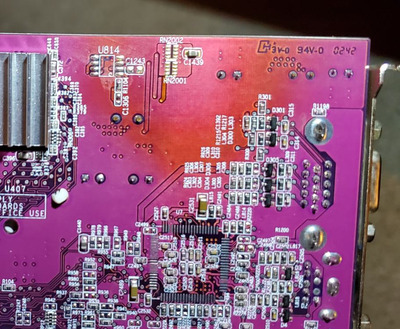

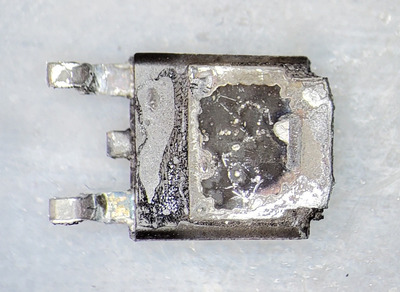

I recently bought this "GeForce4 MX 420" for eBay, which was supposed to be a steal. But it ended up arriving with a burnt up voltage regulator. I recalled seeing some slight discoloration on the rear in the listing photos, but didn't think much of it.

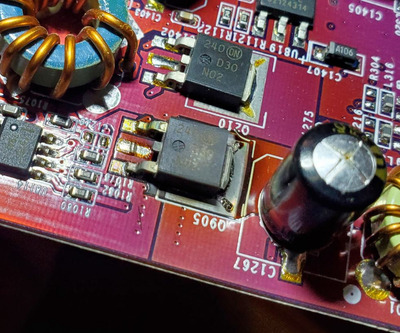

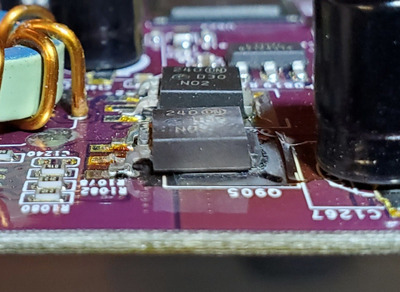

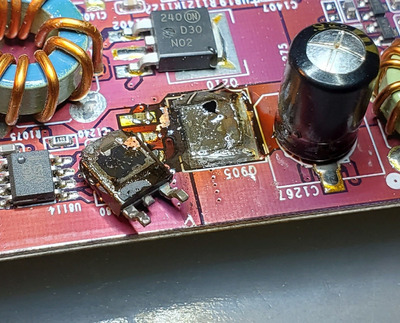

What I think is a voltage regulator is visibly charred, and has even damage damaged the solder mask surrounding it.

I knew from the photos that a lot of the capacitors we're bad, but I was not expecting this. I wonder if the bad capacitors had something to do with the transitor burning up.

The component is identical to the one directly above it in the photos. Can anyone identify what it is?

Edit:

Check this out. Someone else had this same chip blow up on their GeForce4 Ti:

https://www.electronicspoint.com/forums/threa … ansistor.54344/