Reply 20 of 93, by Deunan

retardware wrote on 2021-10-11, 17:09:I always thought, in particular where the DC-DC converters are, low ESR would be helpful.

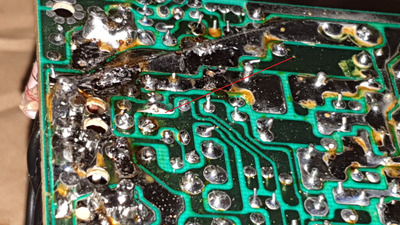

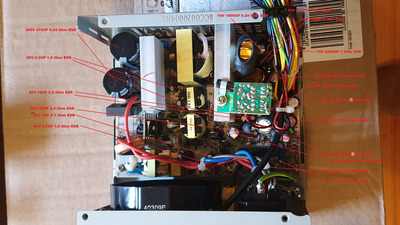

Helpful - yes, in general low ESR is better. But typically not required. In fact a standard electrolytic or tantalum plus some low inductance foil (or better yet, ceramic) capacitor in parallel will not only provide good power rail decoupling, that extra non-aging capacitor will make sure the actual ESR value (for high frequencies) of the aging electrolytic is of little importance. This is not true for the output filters of high current switching mode PSU though, here you have some 20+ kHz spikes when the cap is recharged, and then discharged by load. Even though these PSUs use Pi type filters with pretty beefy inductor between capacitors as primary energy storage, these caps have a hard life at higher loads.

In other words these caps make most sense in the PSU itself, not in the target system the PSU is powering - in theory the system should not care where the power comes from, it should be clean and stable on both linear and switching mode PSUs. If the system in question becomes more stable with switching mode PSU when caps are replaced to low ESR ones, I would always bet the problem was not the caps but the noisy PSU in the first place. So can it help? Yes, but it just masks the original problem, not solves it. This of course assumes the design of both PSU and whatever it powers is not so terrible that it needs all the help it can get to work properly - but that too can be fixed by adding some extra ceramic caps in places where power delivery is marginal.