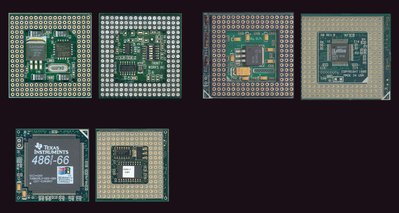

I am not too concerned about the VRM being under the CPU. Here are some examples of popular upgrade companies doing it. One one such upgrade interposer, it ran the Cyrix 5x86-133 "chili pepper". From the name, you get the idea that it ran hot. I've attached one such interposer which is of the same chip we are using, the 486SXL2-66 at 3.6 V. The VRM is under the whole interposer. This configuration ran fine for me at 3.6 V and 80 MHz. I suspect 3.6 V and 80 MHz will be the norm for this interposer board. I suspect most people would prefer the clean look and reduced real-estate of this design. However, I do also like the idea of two models. In the second model "B", how about keeping the trimmer, through hole VRM, and 3-pin header?

In my previous message, I said "orange line", not "orange wire". There is only one orange square line in layout schematic you provided. My hope was that for model "A", the PCB real-estate would stop at the white square line, thus eliminating the extra area provided by the orange square line. If you are not familiar with using upgrade adapters on 386 boards, you may not understand why I am trying to keep the surface area of the PCB the size of the PGA168 CPU. What often happens when using these larger bulky interposer upgrades, the user must stack up male-to-female PGA168 sockets underneith to lift the PCB over motherboard components. I'm hoping to avoid this entirely. For model "A", refer to the interposer example by Trinity Works Inc (provided). For model "B", I suggest making it like the other interposer example, the one with "By D.M." printed on the PCB.

That mini DIP switch is similar to the one I had in mind. Do you want the 8 positions? Also, the part number you listed on digikey is asking for an order quantity of 2,000.

For 6 switches, you may consider, https://www.digikey.com/product-detail/en/nid … 10-6-ND/1853740

Or for 8 switches, you may consider, https://www.digikey.com/product-detail/en/nid … 012-1-ND/948432

These have single unit order availabilities. They are 6 V, 100 mA.

Looks like we can get lower profile (1.55 mm vs. 2.5 mm) with 24 V, 25 mA. I don't expect the current to get anywhere near 25 mA.

6 switches, https://www.digikey.com/product-detail/en/omr … 1116-ND/1811597

8 switches, https://www.digikey.com/product-detail/en/omr … 1118-ND/1811600

I somewhat prefer the dog bone approach because it looks a lot more period correct for 1993-1994 interposers. But if it won't work, then let it go. Any risk with the via-in-hole approach? Is it less reliable for users using a metal-pointed solder iron? I suspect that is what most people would use.

I personally haven't used solder paste before. I suspect this also takes some trial and error - e.g. if you don't use enough, you don't get a reliable joint. Don't heat long enough, don't get a reliable joint. Heat too long, etc... What are your thoughts here? It seems unlikely to me that the user group here will want to experiment with this. I assume the assembler is responsible for putting the paste on. What if too much is put and it bridges junctions?

Plan your life wisely, you'll be dead before you know it.