First post, by dionb

- Rank

- l33t++

Yesterday I picked up a Diamond Speedstar Pro VLB card. Nothing too special, Cirrus Logic CL-GD5428 chip with 1MB. Most pics show it populated with 2x 40-pin 4Mbit SOJ chips, but mine has 8x 20-pin 1Mbit chips - with the locations for the 40-pin chips empty and enticing.

GD5428 should support 2MB, and a 2MB mid-rage VLB card is a lot more interesting than a 1MB one. So I want to add those two chips. Finding 256Kx16 FPM 70ns DRAM is easy enough, but there's more that needs populating on the PCB. There's a (filter?) capacitor next to each RAM chip. The eight for the 20-pin chips are already in place, the two for the 40-pin chips aren't. Unfortunately I can't figure out what rating I should use.

Here's my card:

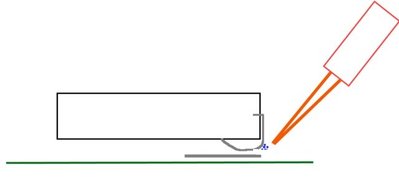

And here's one with the 40-pin chips in place:

C2 and C8 are the locations I suspect I need to do something with.

Two little blobs. Either my eyes are going (quite likely actualy) or there's no code on them. Would a 100nF SMD cap like X7R-G0603 work here?