Hey everyone, apologies for ghosting for a week there - I picked up Red Dead Redemption 2 and got sucked into helping out the fellers for a while, but got tired of hunting and fishing and am now back at it. I also had to order some more alcohol cleaning solution as you go through it fast when trying to keep the boards clean.

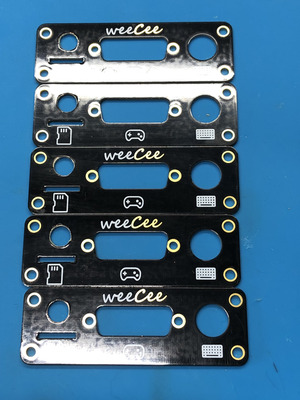

So the update today is mainly around the drilling of the front plate. Overall all of the ones I’ve drilled look good enough - I definitely would highly recommend folk to instead do any cut outs on the PCB itself via forking Rasteri’s work there, even if it means learning a bit of PCB designer, as the results, even when taking into account all the best practices for drilling, are acceptable but not ideal.

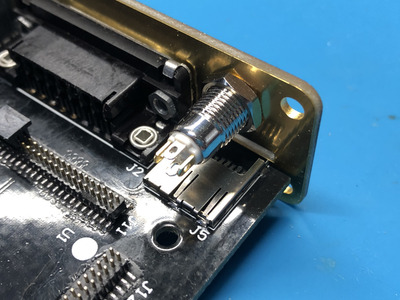

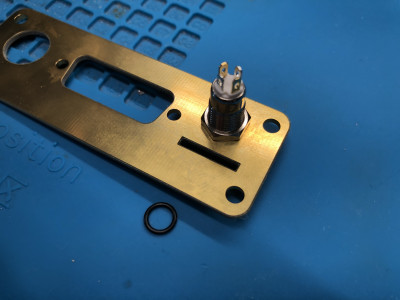

The real saving grace here is that the lip of the drilled hole is going to be covered anyways by the barrel button itself. So the mucky edges aren’t going to be visible in the final product. For sake of viewing, I quickly rigged the plate on to demonstrate both the niceness of it as well as the fact it covers such defects.

Really gotta appreciate all the artists and machinists who do this sort of stuff all the time and can appreciate it when they don’t have to drill holes.

Alas, the testing of the lighting up of the LED inside the button also was fun. Turns out it’s a multidirectional LED where the +/- is reversible, so long as it has the 220 resistor on it. Kinda nice for hooking it up. It’s also a NO (normally open) button which makes it easy to route the - wire to it and then to the RESET pin right next to Battery - pin. So that’s only 3 bodge wires that need ran to it, in addition to the 2 for the battery. Pretty simple setup tbh.

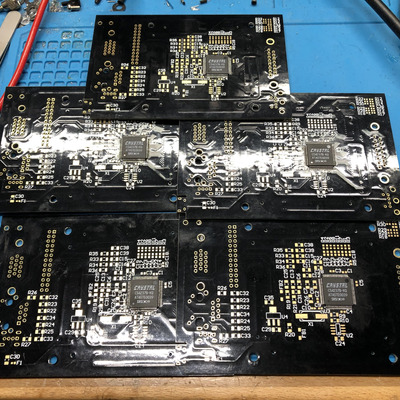

Anyways here’s some pics. Next part is cutting bodge wires to length then soldering them up and putting in some heat shrink piping to make it look clean. Then I will have those that I can solder up and then, at least with the first board, will be able to boot it up and initialize the audio chip. From there just your standard diagnosis to make sure it all works and, debug any issues if any. Here’s hoping that all that handy work worked out.

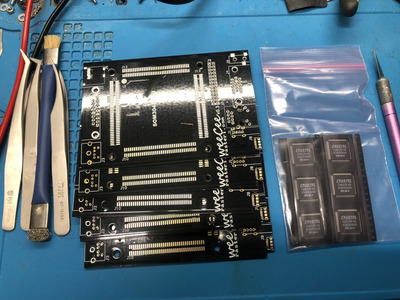

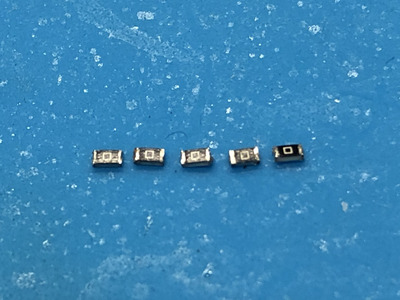

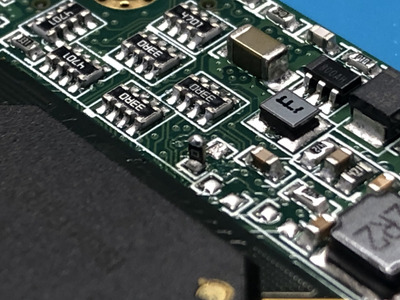

Oh and I still need to tombstone those resistors for the SoMs. I’ll do that next since I have my solder paste out of the fridge.