First post, by vutt

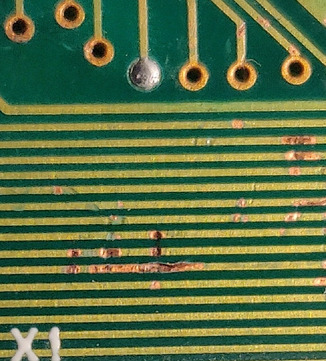

So I managed to score working Sound Blaster CT3670 with visible damage (see attached pic) but fully working card.

First thought. Use electric contact cleaner, then flux and solder exposed tracks over with help of desoldering braid. My concern here is also how to clean tracks so solder will stick.

Then again I may cause more harm by doing so. It is working card after all.

Damage doesnt seem to be mechanical. It looks like some sort of chemical rotting. Will rotting progress by itself if I leave it as it is. Maybe pour over some liquid tape to seal exposed copper?

Any suggestion?