First post, by Boohyaka

- Rank

- Oldbie

Hey there,

Looks like I got my first patient in need of a recap on my hands and I finally need to get to it.

Received this Shuttle HOT-597 motherboard off eBay, sold as "tested working".

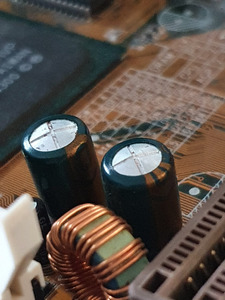

It was immediately obvious most if not all of these bigger green caps were bulging:

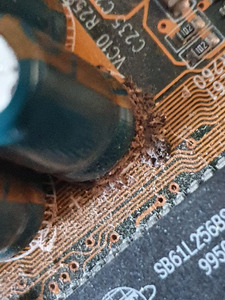

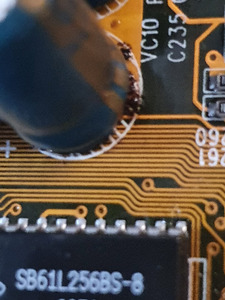

A couple of them have started leaking from the bottom near the CPU socket I believe?

After a quick IPA cleaning, looks like there's no damage to the traces or board. I still haven't removed it all, but that remaining gunk looks exactly like what I already successfully removed, so I guess it's fine.

I have the necessary tools, and got myself a little bit of soldering skills now, so I feel pretty safe trying to fix this. But I have a few questions:

- Is it really possible that the board was still recently "tested & working" - I would definitely not feel safe trying it now with capacitors that started leaking?

- Here's what I think I'll do: take a picture of the whole board and make an numeric ID of every single green cap and its placement, de-solder them all, make a table of ID-rating, and order replacements. Any other "best practices" or general tips?

- There are medium-sized, and small-sized black caps that all look fine and flat to me, only the big green ones are bulging. What would you do - replace them anyway, or just leave them on?

- What should I look for for high-quality, long-lasting caps to replace them? Brand, type, material, whatever - this is all new to me 😀

- As for the soldering of the new caps itself, any specific tips? This doesn't look too hard of a job (famous last words 😁) with the go-through legs, I guess there's a polarity identification to make sure I put them the right way, anything else?

Thanks!