First post, by frisky dingo

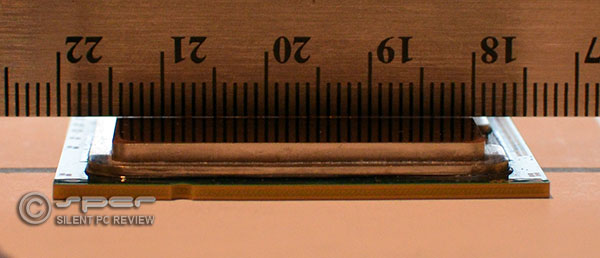

I'm thinking of lapping my 3.2ghz P4 and it's heatsink for fun. Would anyone be interested in seeing that ? If enough people are interested in seeing it lapped I'll go ahead and do it.

I'm more than confident in my ability to lap a cpu. I lapped a xeon W3580 up to 2500 grit aways back, droped about 7c IIRC. I If I lap the P4 it would most likey be to 800 grit. I don't have anything higher than 800 grit and rather not spend the money on it. I might have some higher grit, if I do I will go higher. I should see about a 3~4c drop with 800 grit as both the cpu and its heatsink are pretty scuffed up and uneven. I might buy a sheet of 1k grit, if I do the drop should be more around 5c. That is all of course a guess.