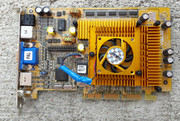

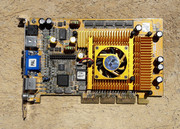

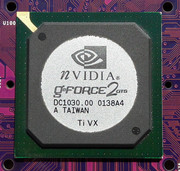

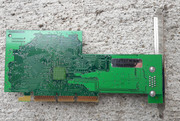

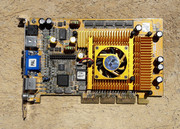

ASUS nVIDIA GeForce 3 Ti 200 V8200T2/DELUXE/64M/P - V8200T2/64MB/(TVR) Rev. 1.00

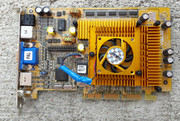

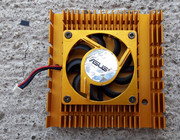

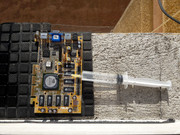

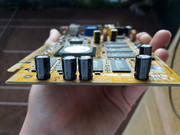

I liked this golden graphic card as soon as I laid my eyes on it 😁 I knew it had some problems, like the missing of the original fan, but given it is was a Geforce 3 Ti 200 I took the decision to buy it. I was assured by the seller that it is in good working condition.

After the work done to restore the Diamond VooDoo 1 and the Creative Riva TNT it was the turn of the Asus Geforce 3 Ti 200, while the purple AOpen Geforce 2 Ti will the last to receive a full SPA treatment.

Said and done!

At first the Asus was looking rather clean as the golden color was very good at masking the dirt and grime.

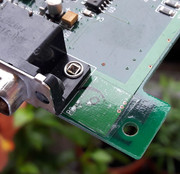

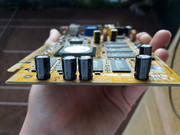

Besides non-original fan, the card has some minor scufs, the tip of some of the push-pins have signs of abrasion and one of the ICs on the PCB has a chipped corner. The good news is that the IC doesnt have the metal insides exposed so it survived. Also the tip of the push-pins stand higher than the rest of the ICs so they saved a bunch of other components. GOOD FOR THEM!!! The paper labels have signs of water damage and the bracket has a white deposit. A green marker was used by someone on some surfaces and labels....WTF!!! ok OK ok OOOOKKKKK!!!! I'm only three and a half years o l d!...

Arrival state

gallery: https://postimg.cc/gallery/1hph2pasm/

Repair

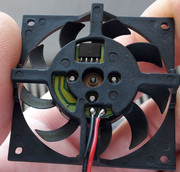

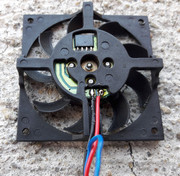

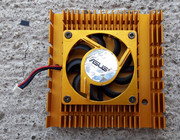

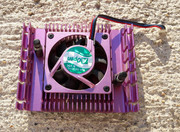

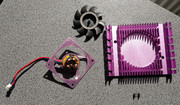

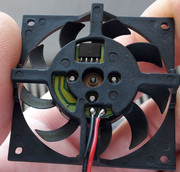

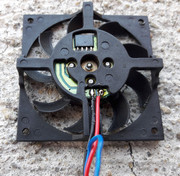

First on the agenda was the fan of the graphic card. Because the cooling system was looking close to the one of the AOpen Geforce 2 Ti, I made a comparison and I found out that the original fan was inverted and the motor was attached to the metal plate that it is fixed with screws. You will see later what I am talking about when I tear up the AOpen. The replacement fan on the Asus has a non standard size so I couldnt swap it with one from by box-o-parts and I had to reuse it. I checked if the original fan wires are long enough and I soldered them to the fan, directly. That meant that the RPM fan (blue) was useless and I put some electrical tape and tucked it under the fan. I also used double sided tape to fix the black and red wires so that the soldered connections werent under stress and in danger to separate. I found four identical screws to fix the metal plate and because the fan label didnt have ebough glue on it I improvised something quick.

gallery: https://postimg.cc/gallery/1vxtd9qq4/

After the fan, I cleaned the rust that was present on the VGA connector, the screw that fixes the metal bracket, the thread of the metal bracket and on the springs of the push-pins. I told you earlier that this card had contact with water.

I used an AUTO, liquid, rust remover. The springs and the screw went into a bottle cap and stayed in solution for 15-20 minutes until I saw some bubbles forming. The rust on the VGA connector was removed with a cotton stick dipped in solution and the rust on the thread of the bracket was removed with a bamboo stick dipped in solution. This rust remover solution really IS THE SOLUTION for my RUST problems 😁. Did I mention I F.....G HATE RUST!?!?!?

The bracket was also cleaned with mild abrasive paste. The push-pins took a bath also 😁

All the parts came out like NEW!

gallery: https://postimg.cc/gallery/2xt0d837m/

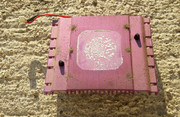

After all this work I was already on a roll, and the cleaning of the heatsinks was piece of cake! Looking good!

gallery: https://postimg.cc/gallery/lcibjp7o/

The isopropyl alcohol 99% bath went well and because I knew the card had some contact with water, I took the precaution to get the alcohol deep under the graphic chip and the memory chips. A BIG A$$ needle was used, the right tool for the job!

gallery: https://postimg.cc/gallery/325nvtj5u/

After these stages I was rather sure the assembly will be painless. Little did I know...

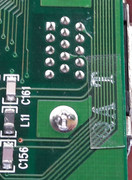

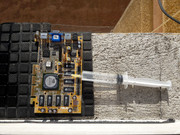

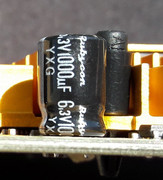

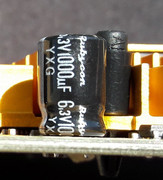

When I first removed the video memory heatsinks I was amazed that no thermal paste or thermal pads were used.

After a close look I found out why thermal paste or thermal pads werent used on the video memory chips. The main heatsink is so low that if thermal pads were used then the heatsink wasnt making good contact with the GPU.GREAT! If they used paste the results could be messy so they left them dry. The heatsinks are just shiny trinkets that didnt make contact with all the memory chips.GG! Asus!!

So I had to do something about this "problem".

ARCTIC MX-4 FTW!!!

THERMAL PASTE TAKE 1 - TOO MUCH!!! Clean up the mess and try again.

Thermal paste TAKE 2 - STILL TOO MUCH!!! Thermal paste comes out from under the heatsinks, clean up the mess and try again.

&#*(!(&^#*(!^~~~~!!!!!

TAKE 3 - What if I try themal pads? NOT GOOD - TRY AGAIN!!!

^$&!^$^~!~~~(#(~&###

I had some SOFT ARCTIC blue thermal pads and I took one piece, put it under two sheets of plastic and used a flat tool to spread it. Afterwards I cut it to size and put it on the memory ICs. ^#!^(!#~~!!!! the push-pins are offset and pressure on the heatsinks isnt uniform so one side sits higher. Paper thin pads are still too thick ...good luck attaching the heatsink for the GPU!!!

Thermal paste TAKE 4 - pls pls pls pretty pls, may the HW GODS smile down upon me 😁

JUST RIGHT!!!

When I put thermal paste on the GPU I also had problems, first it was too little, second time was too much and the third time was just right 😁 This was rather unusual too 😁 never happened to me before 😁

I couldnt leave the memory ICs without paste. It was easier but where is the FUN in THAT!!! 😁

REPORTING IN, SIR!!!!!! At ease PRIVAT AsSsuuuSsS!!!

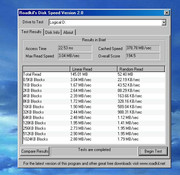

FINAL RESULTS!!!- not bad I might say!

After all this work, that took 8-10 hours over two days, I asked myself, was worth it? You can find the answer yourselves, just look bellow.

gallery: https://postimg.cc/gallery/orkut2xw/

More later.