First post, by sirlemonhead

- Rank

- Member

Hey,

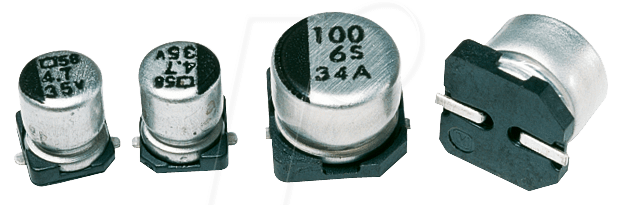

I was taking apart my Dell 466L machine to take some photos of the board and realised I probably need to recap it as the SMD caps were definitely leaking on the board.

I noticed there seemed to be two different sets of pads for each capacitor. I asked about this on the eevblog but figured I'd probably get a better answer here. That thread is at: https://www.eevblog.com/forum/repair/smd-cap- … 232/#msg2315232

This photo should explain all: https://www.dropbox.com/s/1ryd6329nvzidxh/dellsmdcaps.jpg

I'd ideally not want to put new SMD caps on if I didn't have to, as they're a pain to get at in some locations, and the alternative pads would be 10 times easier to solder to.

Should I go with a different type, and if so what could I use?