Lithium grease on the worm-gear, if it has one.

As others pointed out, most 5.25" drives DO NOT.

What happens when "gunk" forms on the linear bearing, is that it eventually causes a rough spalling type surface to appear on them, due to intermittant/improper rolling of the ball bearings in the linear bearing's counterpart, which is part of the head assembly, along with actual dust and dirt being mechanically erosive there as well.

Looks like this.

The attachment spalling.jpeg is no longer available

(Sorry for tiny image. Had to pull it out of google's cache, since my workplace stupidly blackholes anything not inside the USA, and tech sites are a GLOBAL thing, with many in europe.)

This is very bad juju.

If you positively MUST lubricate the linear bearing, consider a very thin application of teflon dry lube liquid. It dries in no-time, and leaves a thin coating less than a micron thick, that is chemically inert.

(example product.)

https://www.walmart.com/ip/DuPont-Non-Stick-D … Bottle/49235098

LESS than a single drop to the whole rail. VERY sparingly.

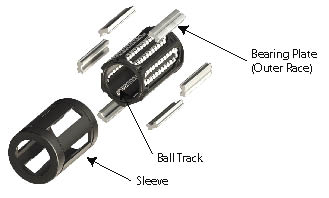

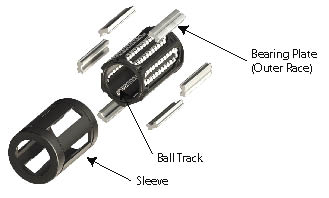

To better understand what is going on, it helps to know what is inside the other side of the assembly. While some more simplistic designs are just a brass sleeve bushing, more sophisticated ones actually have little bitty steel ball bearings, like this.

In the case of a simple bronze one (often for very small bearings of this type), there are no balls, but the tolerances for clearance is basically 0. Any dust in there basically becomes sandpaper, and a "wet" surface attracts/grabs and holds, dust/dirt, basically turning it into gritty sand paper, which then erodes the bearing.

In the case of a ball-bearing type linear bearing surface, if the balls dont "roll" (because friction is too low), then the contact becomes shearing instead of rolling, and it slowly erodes the linear rod.

These reasons are why it is suggested to NOT lubricate these.