If anything I wrote was rude, I'm sorry, it was not my intention to offend. I'm merely being sarcastic, perhaps a bit too much? But I do stand by what I've said.

Jo22 wrote on 2023-01-23, 13:32:

This is respectles, I think. And a bit snobby. I know some of these personally. Some of those socalled "old farts", especially radio amateurs, were pioneers in the 1970s when the socalled "computer hobbyists" or "computer enthusiasts" developed machines in the style of the IMSAI 8080 or Altair 8800.

I don't think that is relevant here. First computers were made with relays, then vacuum tubes, then individual transistors. I dare say both the tech and the test equipment have evolved a tiny bit since then. If someone prefers to use old, analog meters because - and this is obvious from your explanation too - they are old and that is what they're used to, fine, let them. But to actually seriously suggest that anything but the highest end analog meters are any match for modern digital ones is... dubious, at best.

Jo22 wrote on 2023-01-23, 13:32:Just because you prefer digital multimeters doesn't mean that other types of instruments are obsolete.

Personally, I think that […]

Show full quote

Just because you prefer digital multimeters doesn't mean that other types of instruments are obsolete.

Personally, I think that digital multimeters with a virtual analogue instrument would sell especially well for high prices.

Just look at nowadays smartwaches with digital analogue faces.

The clock faces/backgrounds are an entire market on their own.

You have a fondness for analog stuff. So do I in fact. But do not confuse your fondness for usefulness, and certainly make sure any advice you offer take that fondness into account. As for your idea of mixing a bulky, fragile analog indicator into modern, rugged handheld... Let's just say I will stand corrected if and when you'll make some money on that scheme. Yes, there is a huge market with all kinds of idiots with entirely too much money on their hands - be it watches, audio equipment made with unicorn blood, or "sport" cars. But I am at least hoping actual engineers will not fall for it.

Jo22 wrote on 2023-01-23, 13:32:I don't mean to be rude, but did you actually read my post and my explanation?

It's not about the technology as such, but the vi […]

Show full quote

I don't mean to be rude, but did you actually read my post and my explanation?

It's not about the technology as such, but the visual representation.

A bog standard digital multimeter has numerical representation only.

A classic multimeter has a small latency which results in a smoother movement.

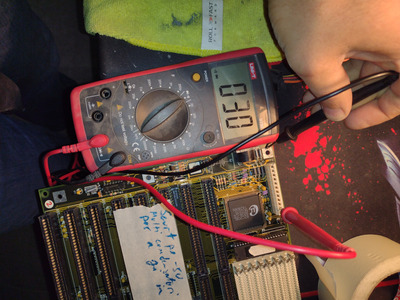

I did read it, and now I suspect you have never held a modern meter in your hands. Or just the really cheap 1$ wonders from supermarkets. Ever heard of a bar graph? Refreshed at, at least, 10 times/s, except not susceptible to orientation, vibrations or parallax effect. And that's for the cheaper models, bit more expensive meter will have actual readouts at 10/s and the graph at 3-10x that. With at least 3.5 digits of resolution if not actual accuracy. Which analog meter, that is not a heavy bench (and possibly AC powered) model, offers miliohm resolution? Because we are still talking about finding shorted tantalum capacitors on a motherboard, not how to build a tube radio and feel like it's 1920 again - right?

Jo22 wrote on 2023-01-23, 13:32:

(...) Back in the day, high-impedance tube voltmeters were used, too.

I'm going to say that I like tube meters, even more than I like any other tube electronics like radios, TV, or even scopes . I even use - as in, an instrument, not something to just look at - older frequency counter with nixie display, though that's the only tubes it has. I would not, EVER, recommend tube-based devices to anyone, except maybe as a fun toy and/or a prop for YT. But I will stop here, I think I've made my point clear enough, I do not want to argue this any further. If you wish to so, please PM me.