Looking at costing options, I noticed that for the SXL2 interposer, the following:

6-layer is $60, sale is $2

8-layer is $86, sale is $2

10-layer is $187

12-layer is $257

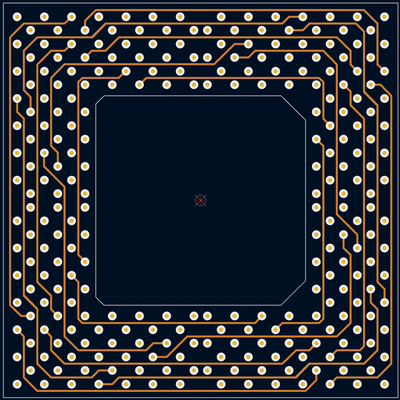

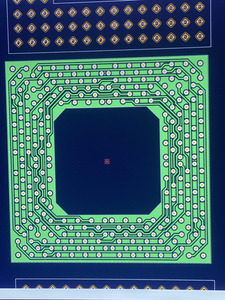

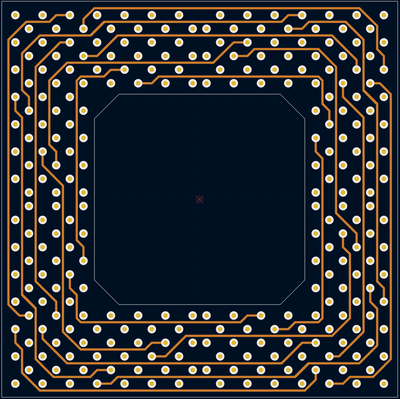

The cost to prototype 6-layer is $26 more than 8-layer. So if I needed to run a beta 1 and then beta 2 batch, the cost would be $120. if we do 8-layer and add ground plates between the data/address planes, it is $86. Seems like 8-layer is the way to go, assuming the first prototype works well.

10- and 12- layer are far too cost prohibitive.

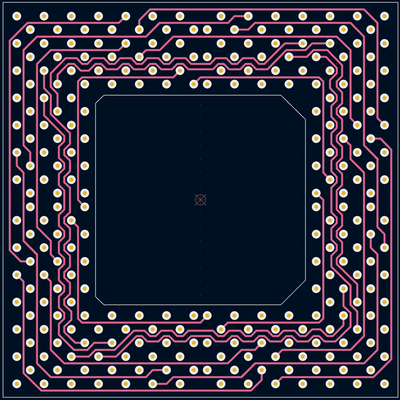

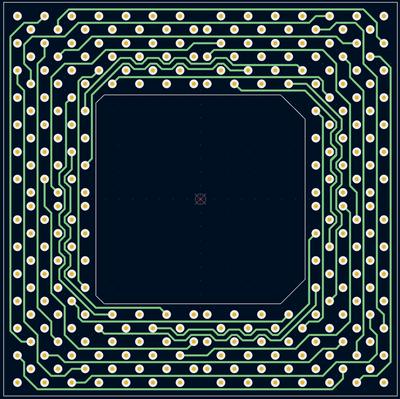

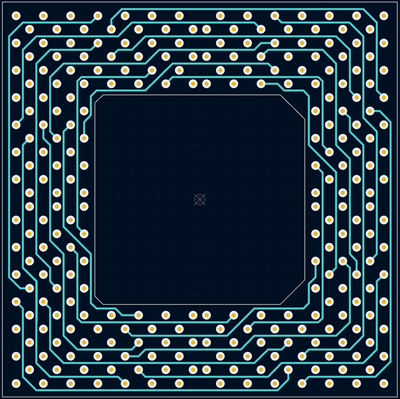

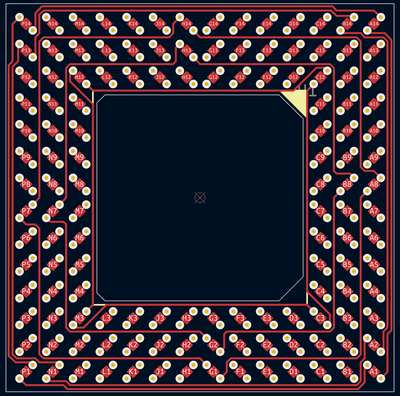

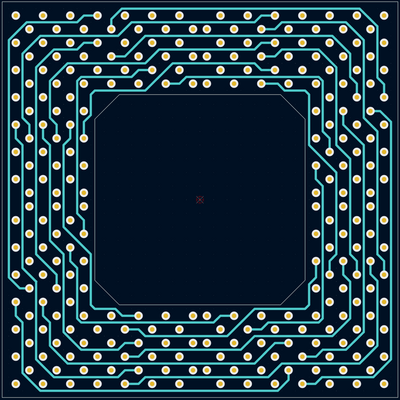

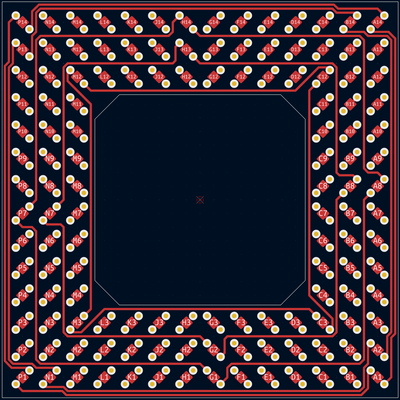

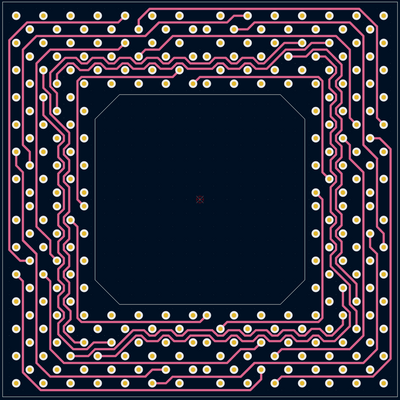

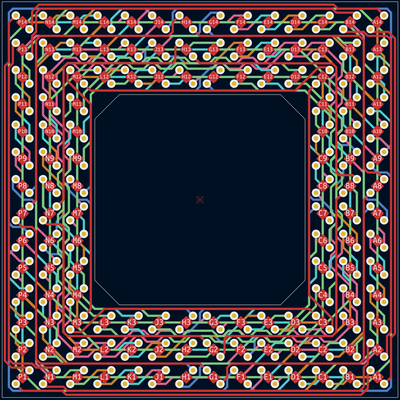

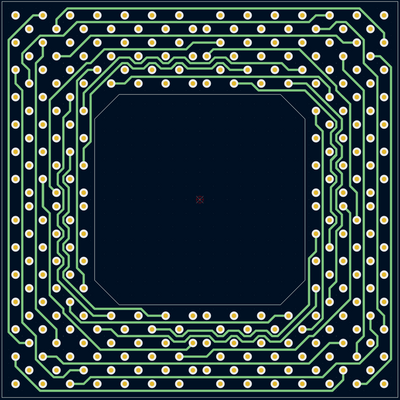

Why don't you want traces going through the middle? Seems like the middle region would be the preferred approach because traces would be going past less signals/traces. Also, less probability of having an issue with solder shorting the trace to PGA pin pads. Whatever the case, you'd still want to have physical PCB material in the middle for rigidity.

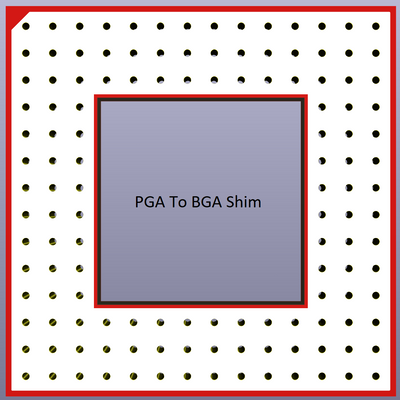

Regarding assembly, what is the difference between SMD and BGA for this application? I don't think I can BGA solder a 2-piece PCB sandwich together with any degree of certainty. The probability for a bridge is too high, and it won't be visible. Any mistake and the unit would need to be disassembled.

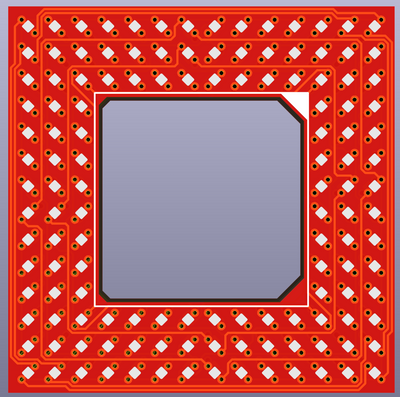

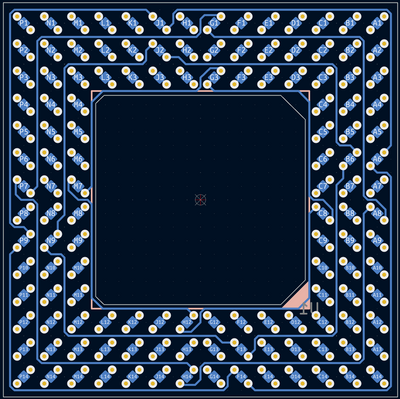

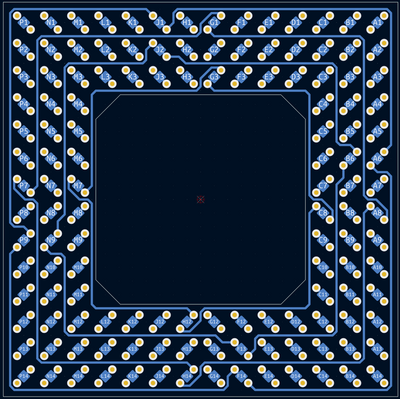

My idea was to have a single PCB with both sides as surface mount for the PGA pins.

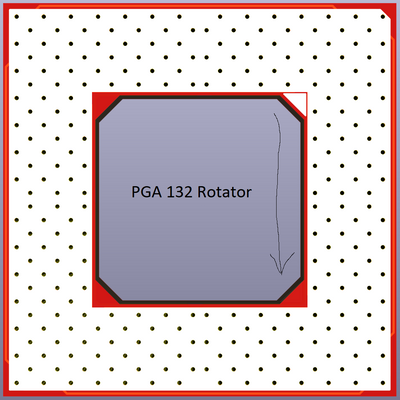

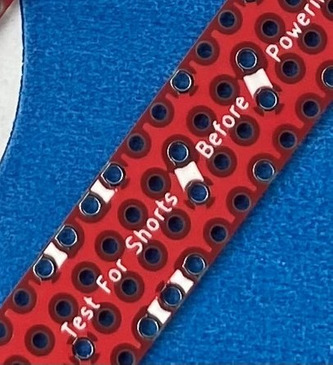

Then I would take the same male-to-male PGA pins used with the SXL2 interposer and place them into a temporary PGA132 (386) socket. The purpose of this socket is for alignment only. In the photo, I'm only showing a few rows of pins, but during assembly, 132 pins would be inserted.

Next, apply solder paste to one of the sides of the PCB.

Now place the male-to-male PGA pins with the 386 socket attached onto the solder paste.

Use hot air to solder these PGA pins in place.

Then remove the 386 socket. Proceed to the other side of the PCB, but instead of using male-to-male PGA pins, we'd use male-to-female pins.

I would need to use a fairly generous amount of solder paste to ensure the PGA pins are held tight enough to the PCB. Ideally PGA pins with shorter legs would be preferred.

Plan your life wisely, you'll be dead before you know it.