First post, by quicknick

- Rank

- Oldbie

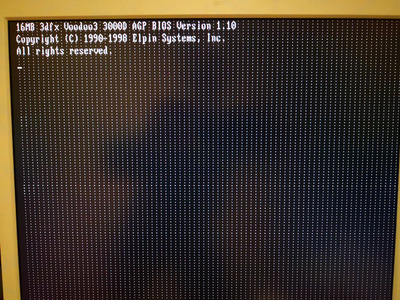

Got this Voodoo 3 from today's flea market, but when I got home it turned out that the green spots that looked like corrosion were really corrosion 😐

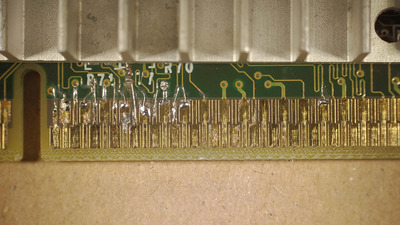

They even reacted (bubbled) when I bathed the card in vinegar, so who knows, maybe the card was stored together with some leaky 286 boards or whatever. Here's how the most damaged part looks like, after scraping most of the green gunk and lightly sanding the 'fingers' :

I'd say it's pretty bad, gaps on at least two traces (Vddq 3.3, AD17) and a few more that definitely need reinforcing. Soldering on/near AGP fingers gives me the shivers, and I can almost envisage all their surface engulfed in solder...

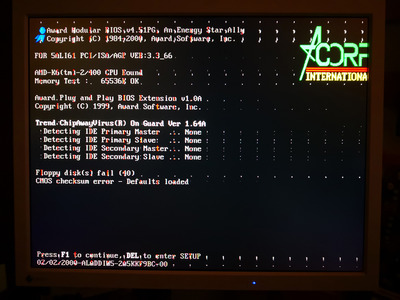

There's also some corrosion between the top RAM chips and on a couple of vias near the vBIOS, but these areas don't look nearly as bad as the one near the AGP connector. I'll leave here a few more photos:

So, any ideas on how I should tackle this? Bin the card, pray to the Voodoo gods, try to bridge the gaps with very fine strands of copper wire? Is kapton tape suitable for keeping the solder from 'wetting' the entire golden finger when soldering on it?