First post, by clownwolf

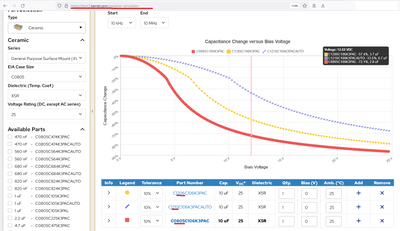

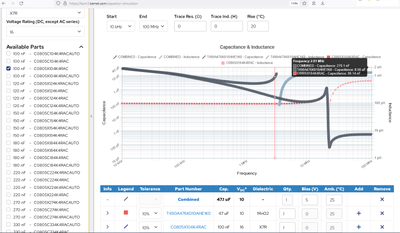

I am looking to replace *10uF tantalums for my Turbo XT motherboard, but I am looking for something other than electrolytic. I used electrolytics to re-cap my IBM 5160, it works great, but I didn't really like how it looks now.

Based on other threads, people were recommending replacing Tantalums with MLCC ceramics. I am willing to try that, but would a through hole ceramic work as well? something like this:

https://www.digikey.com/en/products/detail/td … 06MRT06/7384735

Unfortunately the datasheet does not say how much ESR these things have, so I can only measure it if I buy them. Its also non-polarized, but I assume that's not a problem.