First post, by lowlytech

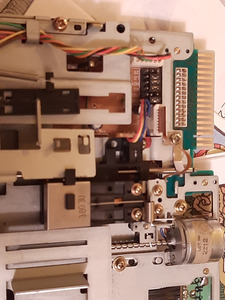

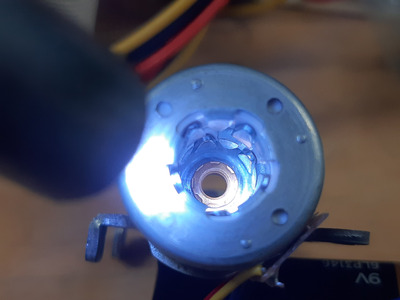

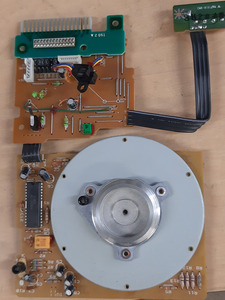

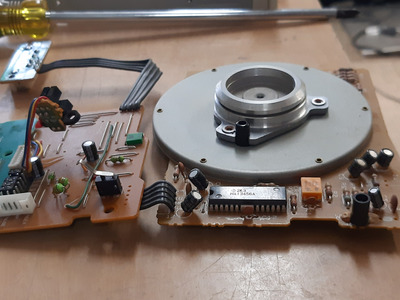

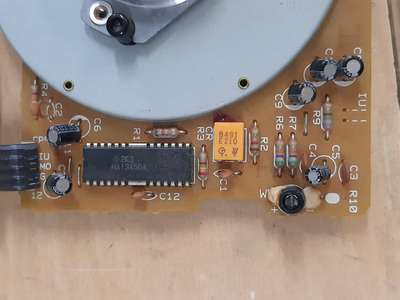

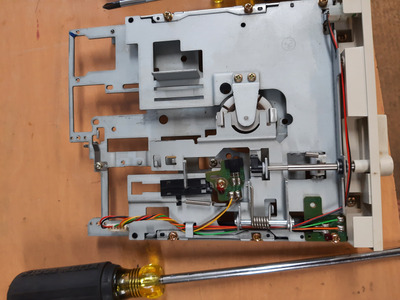

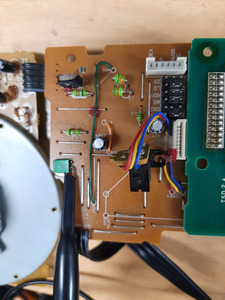

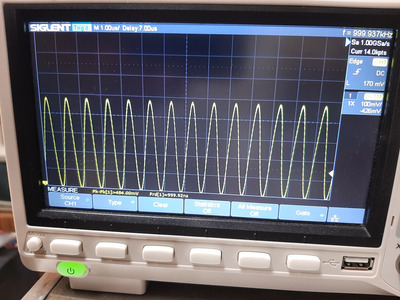

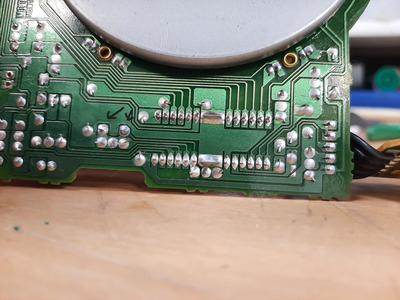

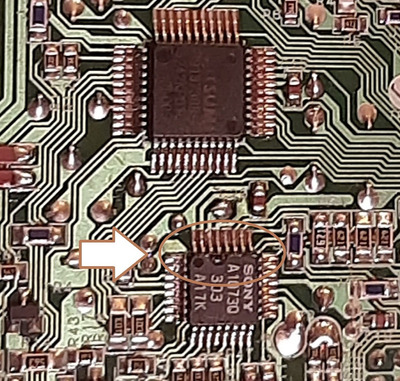

I am going through my collection and trying to find a 5.25" drive for this epson equity machine I am working on. So far out of my 4 5.25" drives, 3 have the same fault, no spindle motor activity. The head seeks on POST, but anytime a disk is inserted it is like the motor just doesn't get the signal to turn on. The 4 drive does spin the motor, but the locking arm mech is busted. Unfortunately all 4 drives are all different brands, so no cobbling together for a working drive. I have since changed floppy cables, controllers, and even moved over to a slot 1 pII board with built in FDC to have a sanity check , and all 3 drives will light up like they are accessing the drive, but the motor is just dead. I checked for good 12volts on the boards where the motor is attached.

Now my question, do you think the original epson floppy controller killed the motor driver IC perhaps? I find it pretty unlikely to have 3 drives with the exact same fault and one of the drives I know 100 percent was good that was pulled from a 486 years ago and stored in a box with foam in my office, so good conditions.