First post, by psaez

Hi

I desoldered a broken capacitor, and when trying to solder the new one, I accidentally mixed with tin a point with the hole of one of the legs of the capacitor. Now it's completly impossible for me to unmix it. I tryed everyithing. flux, cleaning, desolder tape, etc...

I removed again the capacitor to try solving it, but I can't.

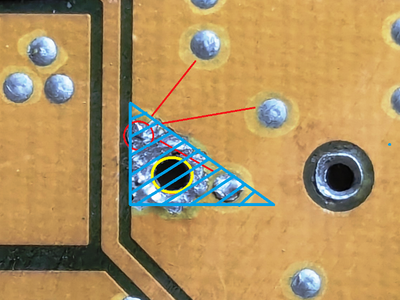

I'm attaching a image of what I mean. The yellow circle is one of the holes for soldering one of the legs of the capacitor. Do you see that the back of the motherboard is full of points, I rounded in red some of them. The photo is super zoomed, so between the mixed one and the hole of the leg of the capacitor is only 1 milimeter or even less.

You can see a red circle in the place where the mixed point was before mixing it. I added some red lines to show exactly equal points to show you what i mean with a "point".

Please can someone tell me how to solve this? Is my only working tualatin motherboard.

PD: on the other side of the motherboard, in the reverse place of these small points, are exactly the same, a small point. Don't know what is the purpose of these points. Someone know?

this is the other side of the motherboard, where i used the same colors and signs to clarify which hole is which hole. As you can see, the condenser pin of the positive pole is the mixed one. Does that confirm that it is ground and it is safe to mix those circles with the negative dot of the condenser with tin?

The motherboard is this model: https://theretroweb.com/motherboards/s/dfi-ca64-tc

And the damaged condenser is this one: