First post, by lowlytech

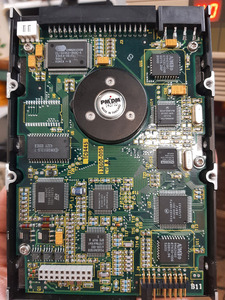

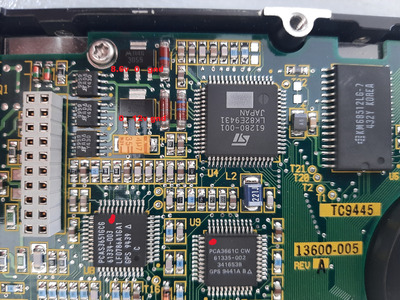

Have a conner 420MB ide that worked perfect, had used it several times in the past with zero issues. Pulled it out of my parts tote today to install in my 386 build i am revamping and the drive is dead as in absolutely no motor sounds, no ticking, nothing just dead. I confirmed that 5v is present on various parts of the pcb. Nothing gets hot on the pcb anywhere. I tried two different power supplies too, but can confirm the molex connection on pcb does show 12v. Any ideas on what I should focus on?