First post, by sam95

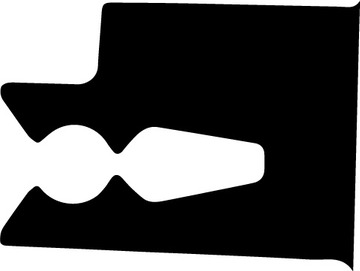

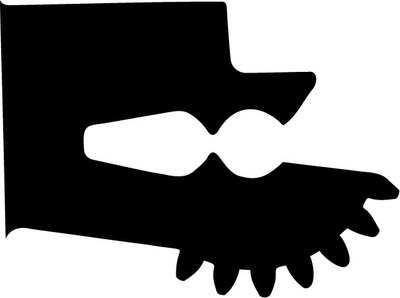

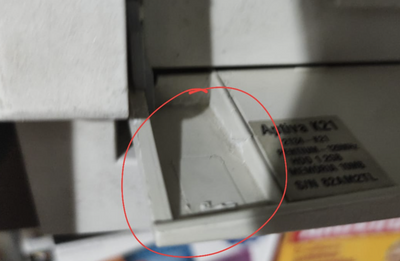

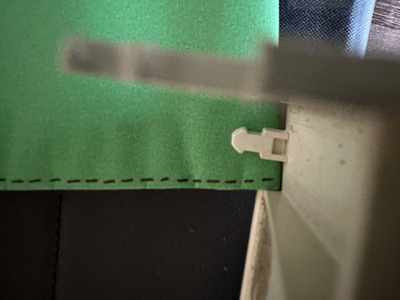

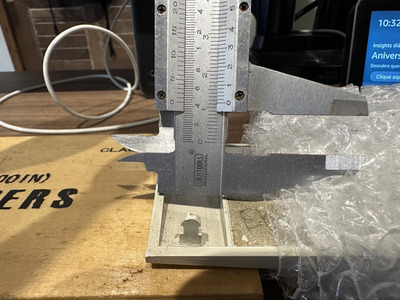

I just bought an Aptiva 2144 that took a tumble and part of the front console and the front panel hinges are broken. I want to restore it to its full glory. My plan is to model the broken sections, 3D print them, and fuse to the original part (also got some metal to unbend).

Front console seems straightforward, as it should be roughly symmetrical and I can copy the other side and mirror.

But the hinges, I've never seen them not-broken. So here's the ask: can anyone with a Desktop Aptiva (model 2144) take the front panel out (big ask) and upload some high res images with scale so I can model them?

I imagine this could end up being useful to more people, as I've seen more than a few 2144s with broken hinges.

Attached gory details of the busted boi I'm waiting in the mail.

Cheers!