boby wrote on 2024-01-09, 21:42:

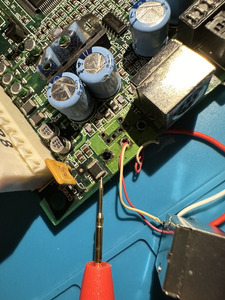

But I Think I found the issue. On the image bellow there is a probe pointing to this component FB1, which I have no clue what it is, but the power trace from the kb, leads to it. However, when powered on and kb connected to original pins, this component shows 5V on the side where the probe is and 2.5V on the other side. So here is where voltage drops. What is this component and how to get a new one?

bingo! as DerBaum and weedeewee already explained its an inductor, its there to take care of any power spikes.

Simplified explanation: Inductors want to only conduct direct current and resist any voltage level changes. Capacitors on the other hand love conducting Alternating/jumping signals (AC) but will resist steady ones (DC). When you want smooth power you route supply thru serial inductor and put couple capacitors between positive voltage and ground for good measure. Inductor will do its best (like a car damper in the suspension) to only pass smooth steady voltage level, optional capacitors will take care of any eventual spikes by quickly conducting those to ground.

Why would and inductor want to block voltage swings? Lenz's Law! Here a cool demonstration https://www.youtube.com/watch?v=N7tIi71-AjA

weedeewee wrote on 2024-01-09, 21:49:

I wouldn't be surprised that it splits in two when you try to remove it.

I think this might be original defect of this motherboard, and its a design one! SMD inductor is too close to edge of PCB and keyboard/mouse connectors. Pulling on keyboard/mouse cable up/down will eventually crack it. Quite possible it was working intermittently for a long time after initial damage. I can imagine shenanigans like

- plugging only keyboard works fine because some keyboards will still somewhat function with degraded supply

- additionally plugging mouse either bends the crack more resulting in higher crack resistance and not enough power for both, or the mere mechanical action/weight of mouse cable breaks connection, unplug mouse and it starts to work again. User sees random behavior and goes crazy 😀

At least it wasnt an SMD capacitor in this unfortunate placement. Unlike breaking Inductors SMD Capacitors tend to go short, and it can get quite spectacular 😀 Story about capacitor failure caused by same mechanical reason - SMD component placed near PCB edge where user induces mechanical stress.

EEVblog #1036 - PSU Fire PCB Repair https://www.youtube.com/watch?v=VwdnGbI5ls8

EEVblog #1037 - Solving Ceramic Capacitor Cracking https://www.youtube.com/watch?app=desktop&v=QgKY5QWehME

boby this is really good news. Compaq let slip a design defect, somewhat fragile component sensitive to bending was plopped on board edge right next to connectors experiencing mechanical leverage every time user plugs/unplugs/moves cables. I bet this was your original failure, PS2 connectors were fine, but just plugging/unplugging something was causing intermittent power delivery. Fix is super easy, desolder FB1, replace it with a jumper (piece of wire). Inductor is non essential, its there in case someone doesnt read the instruction and plugs PS2 devices into a powered computer.