First post, by Turboman

- Rank

- Member

I want to build myself a high end PC and I went through an old box of mine and found a board that was ruined years ago 🙁 I was wondering if it is possible to repair the broken pins and put a new socket on?

I want to build myself a high end PC and I went through an old box of mine and found a board that was ruined years ago 🙁 I was wondering if it is possible to repair the broken pins and put a new socket on?

Umm... You aren't local are you? That is IDENTICAL to one I threw on the trash pile in my garden a few weeks ago, so if you got it from there it won't work, it fried, so don't try (It's dark, so I can't check if it is still there). It's a Biohazzard anyway, so I'd bin it personally, but a lot of people like this model.

Otherwise, yes, it will be tedious, but you should be able to repair it. You would probably be best to try and remove each pin as well as it's solder and attempt to replace the entire socket. A quick replacement could be done by installing SIP sockets on each row. The alternative is tracking a socket down or baking off of a dead board which is a REAL pain in the ass.

Just keep reminding yourself, it's far worse repairing a CPU, I had to replace missing pins on a PPro Q0004... Now that was tense, but worth it other than me feeling ashamed of my shitty soldering when I had to video the machine. Interestingly, that was what I think I destroyed that socket for in the first place, as I used it to guide the small pins into place and then used a busted 462 boards socket for the staggered pins. You won't have to worry about any of this. Just saying so you can be like "It could be worse" if you decide to mend the socket.

Lol, I am in the US, I have some dead boards with sockets intact. I just don't know how well I could do this I'm experienced with soldering but not that experienced.

I do have a Tenma Hot Air Rework Station with different nozzles.

The socket is through-hole... As long as you have a decent soldering iron and a steady hand it should be doable. A pain, but doable. Since you have dead boards to get a socket from, you risk wasting nothing but time.

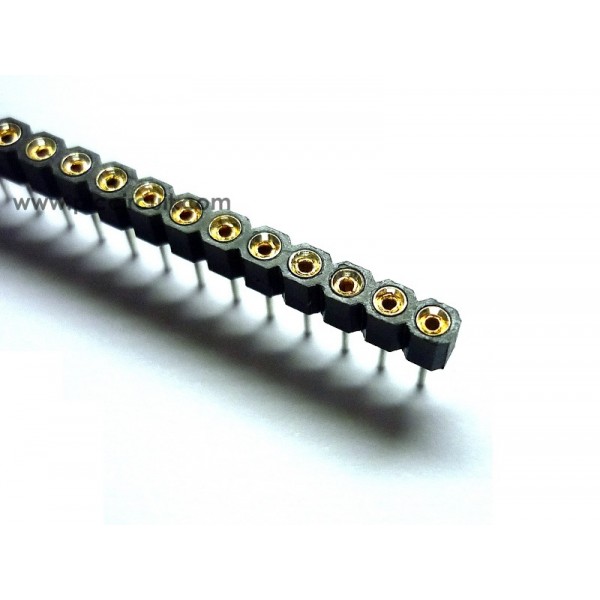

Really, just use SIP sockets;

Some Socket 3 devices (usually SBCs) had sockets that were like many of those molded together. It will be easier because you can make them smaller so you don't have to worry about removing the old solder and getting every pin in at the same time to solder.

To remove a socket from another board will be time consuming and risky, you would need a monster hot air gun or an oven with pretty precise temperature control to get it off. I suppose you could use a de-soldering iron and a lot of patience, but I have no experience with that tool as they are hard to source here.

wrote:To remove a socket from another board will be time consuming and risky, you would need a monster hot air gun or an oven with pretty precise temperature control to get it off. I suppose you could use a de-soldering iron and a lot of patience, but I have no experience with that tool as they are hard to source here.

In theory, he could do it with a soldering iron and a spring-loaded solder sucker, though the amount of patience this would require is inhuman. +1 vote for SIP sockets.

Ugh, those things are the bane of my existence, they work for a while but then pieces of hot lead start falling back out and stick to things you don't want them to. As soon as you open them to clean them they stop working properly. Or it could be that my first one was from Boyes (a cheap shop mostly known for selling shower gel, clothes, fabric and sewing supplies) and the one I've used for the past decade came free with a subscription to Real Robots magazine for what I never discovered, as the robot they sent you in pieces was a solder-less construction.

I would have the deepest respect for anyone that could remove something that large with one of those tools as I struggle with 16-Pin DIPs.

I've disassembled and reassembled mine a few times, and it still works just fine. Still, I wouldn't want to even try to desolder something like a socket with it. After having to remove the connectors of an Arduino board (and with a colleague helping, even), I started seriously considering purchasing some better equipment.

wrote:Can you link me to where I can get the proper Sip Sockets please?

Oh, I also have a motherboard that has the old style large Sip stye socket could that work?

(image)[/url]

If you have the patience to desolder it, yes.

Just bash "SIP Socket" into eBay or check your local electronics place. Socket 3 has 237? Pins and bags of ten 40-Pin SIP sockets are easy to track down. It's a generic component, every manufacturer makes them slightly different cosmetically but they are near enough identical in practicality. If they look like the one in the image I posted, they should work.

This was written before the post was edited and Alexanrs replied, so in response to the new posts;

Yeah, it would work if you have enough patience. The pins were always the same pitch and diameter.

@Alexanrs; Wait until you start working on SMD. That gets really fun, especially SOJ.

Ok, thanks guys, when I get around to it I'll post my progress.....and if someone ever has a high end 486 board or one like this for sale I'd be interested 😁

Going with HighTreason's recommendation as well - unless your can find a PGA socket with a proper footprint for cheap (which is not that easy in my experience - but then again I've only looked for 68030/68882 ones in the past) or even a suitable ZIF socket if you're lucky. If there are too many pins in individual places you can usually remove them by pushing them out from the bottom (might require a moderate bit of force).

Some examples from eBay (which may not be suitable for your board - I didn't check the pincount and arrangement):

http://www.ebay.com/itm/3-PIECES-280-PIN-PGA- … =item19ed72a5c3

http://www.ebay.com/itm/MOLEX-67276-3700-ZIF- … =item4cf6051a13

When using SIP-strips put them on the CPU and the resulting contraption into the solder holes before acutally soldering them to the board, so they're aligned properly. Might seem like an unrequired step but nothing worse than soldering 250 pins to realize one row might be off along with the following ones so the CPU doesn't fit anymore.

Current Project: new GUS PnP compatible soundcard

[Z?]